Sectors. This is where we excel.

Agrifoodtech

Kepser is a leading player in the agri-food tech sector, specializing in the manufacture of high-quality components and solutions for the agricultural and food industry. With deep expertise in metalworking, we develop customized products and assemblies that contribute to efficient agricultural and food processing equipment.

At Kepser, we invest in advanced metalworking equipment and collaborate with our customers to deliver customized solutions that enhance the agricultural and food processing chain. Want to strengthen your agricultural and food processes with high-quality components and solutions?

Circular Economy

Kepser is your partner for co-engineering and manufacturing a wide range of solutions for the circular economy. Aligned with our commitment to circularity, we aim to provide work tools that are not only safe and efficient but also leave a minimal ecological footprint.

Our products are made with sustainable materials and innovative construction methods, contributing to a circular approach in internal transport. At Kepser, we have the necessary expertise, advanced production facilities, and a dedicated team to meet your long-term solution needs.

The future doesn’t wait. Call and ask about the possibilities.

New Energy

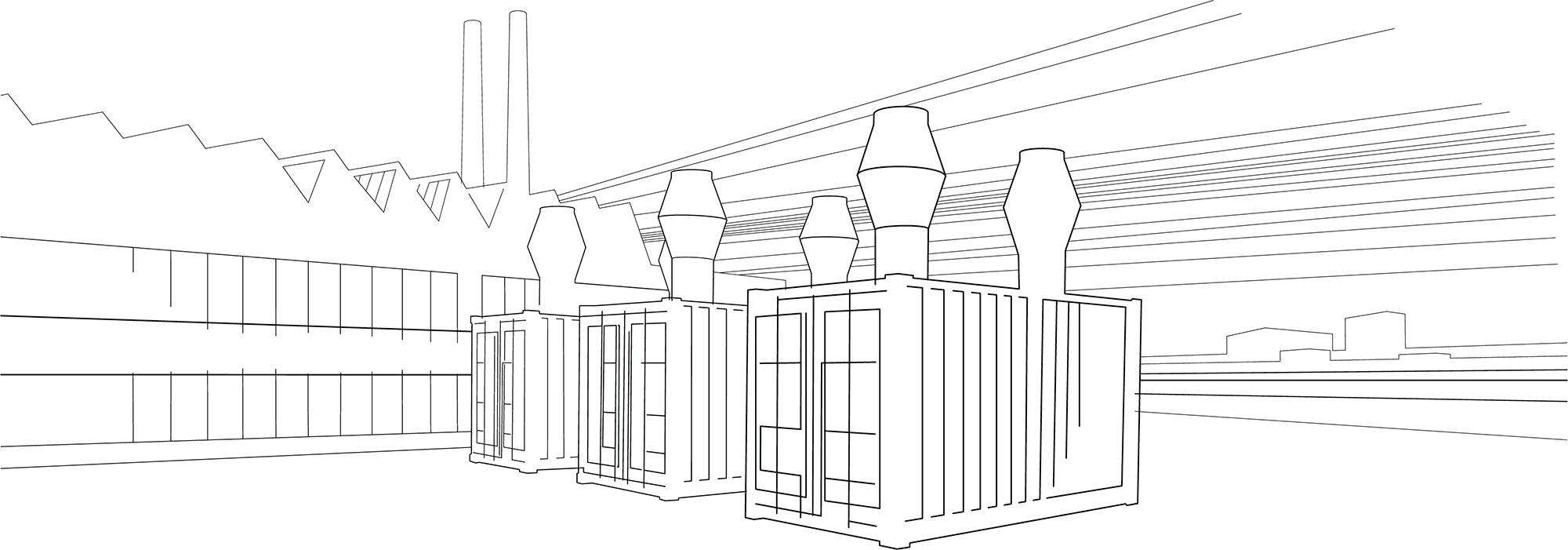

At Kepser, we are energized by the 'new energy' sector. As a metalworking company, we eagerly take on our role in manufacturing sustainable energy solutions for the future. Focused on producing high-quality parts and systems for sustainable energy applications, our company specializes in custom-made constructions, assemblies, and components crucial for various sustainable energy solutions and green technologies.

Our products include precision-engineered metal components, reliable parts for solar energy systems, hydrogen gas, and other innovative energy generation equipment contributing to cleaner and more sustainable energy production. Our custom-made metal products offer innovative solutions for the challenges of the 'new energy' sector, making new possibilities achievable.

Do you give us new energy with a challenging assignment? Send a message.

Food

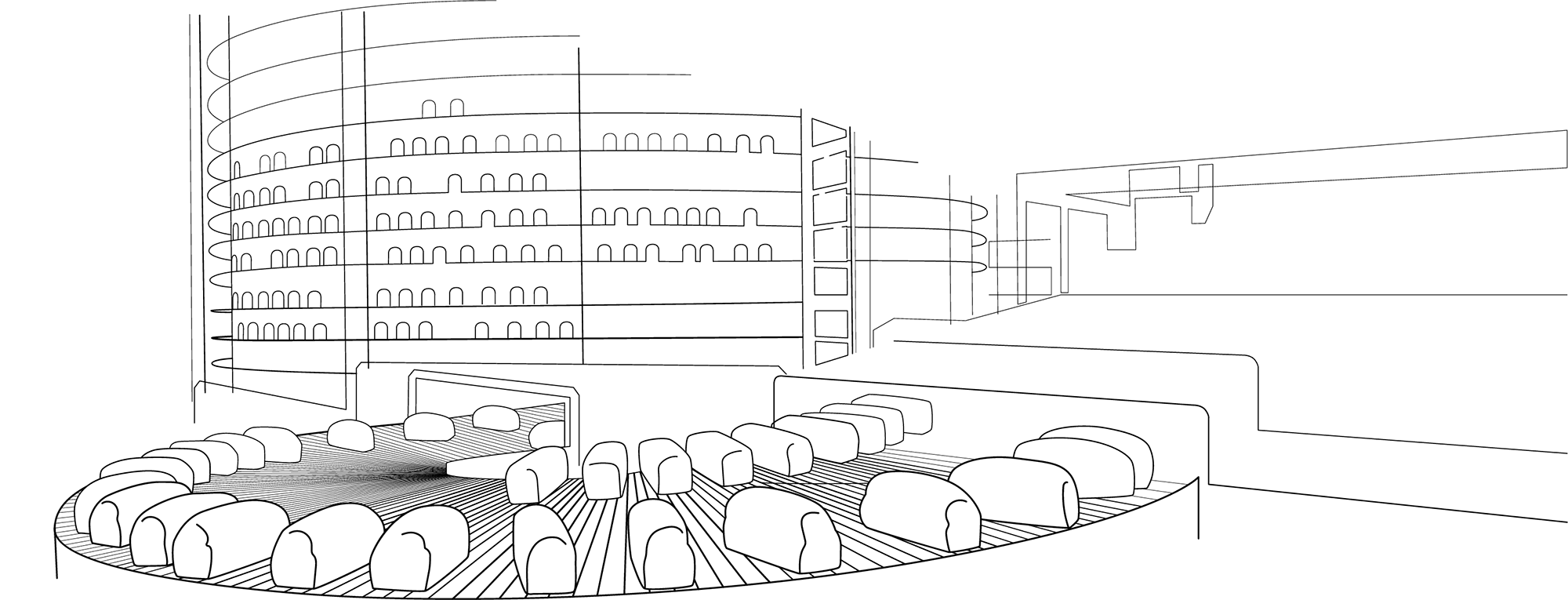

Smart design and the right choice of material for machine parts are extremely important in the food industry. Kepser primarily uses stainless steel for this sector on account of its ease of cleaning, low adhesion of bacteria and excellent corrosion resistance. We use our profile laser to process tube and hollow profiles. These are then used to make closed frame constructions for the food industry which are naturally easy to clean.

We are familiar with all the rules and regulations such as EHEDG and HACCP. We also know what having to be able to clean a machine properly means in practice – and hygienic welding holds no secrets for us. With our barcode tracking system, you can trace the exact origin of (certified) materials. We believe that transparency and traceability are not just mandatory requirements in the latest machinery directives for food contact materials, but are crucial in the food industry. We would be happy to tell you more about the possibilities that we have to offer the food industry. You can contact us at any time to arrange a personal appointment.

We know about food. Call to find out about our solutions for the food industry.

Packaging industry

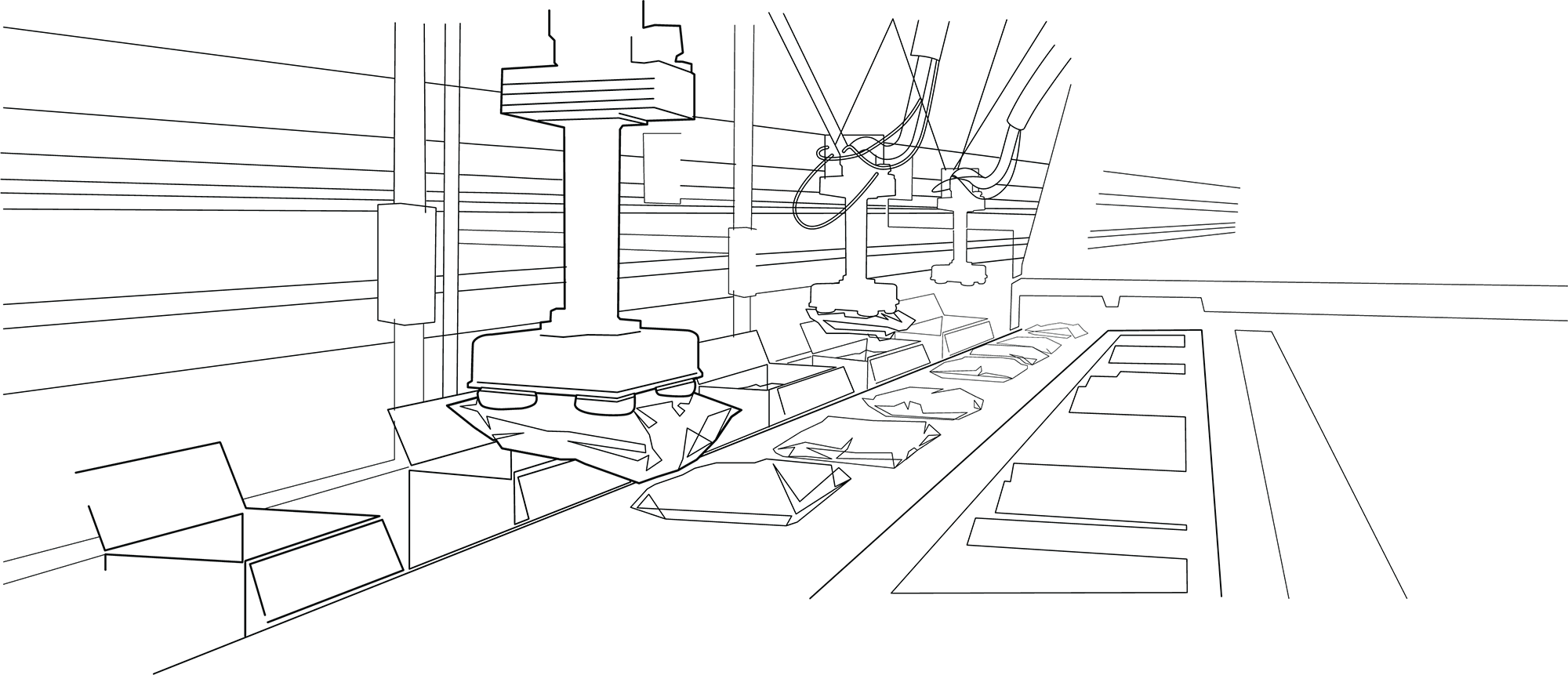

Kepser has been making metal components and subassemblies for the packaging machinery for years. They are used in all kinds of sectors and can be found in applications such as cartoning systems, flow packers, stretch wrappers and filling, closing and bulk packaging machines. We love wonderfully innovative solutions for the packaging industry, whether they are standard machines or customised machines that we develop by collaborating with our customers.

We make parts for robust and efficient packaging machines using the latest technology. We also supply complete machines and are able to take care of assembly and surface finishing. The sheet metal work, the frames, the rotating parts: since we produce all parts inhouse, we can always supply complete modules quickly and to our customers’ precise requirements. Please do not hesitate to contact us should you wish to find out more about what we can offer the packaging industry.

Call for advice from one of our packaging experts.

Transport

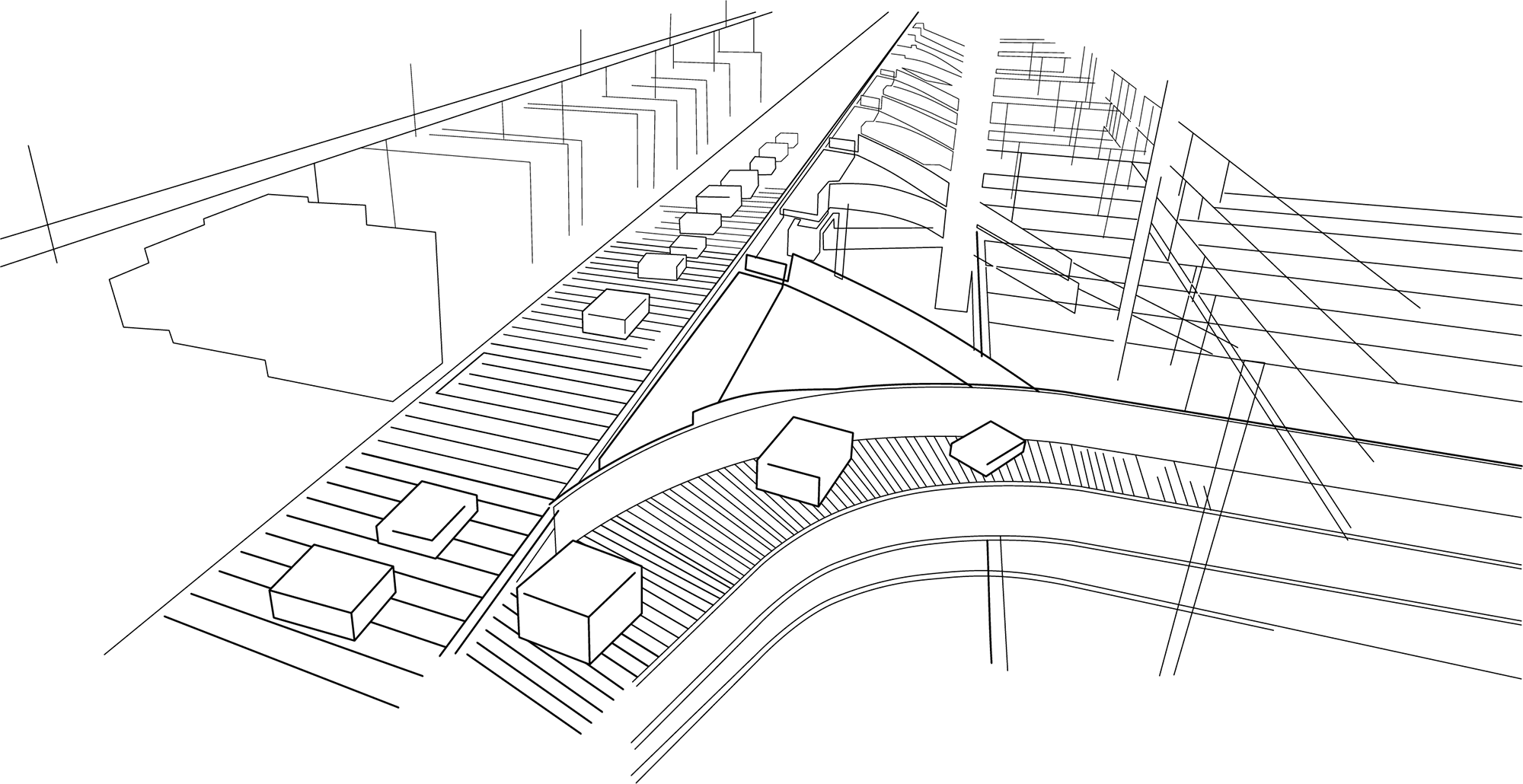

Kepser produces a wide range of products to facilitate the moving of heavy goods in-house. They range from simple wheeled containers, stackers and parts for forklift trucks and transport trolleys to more sophisticated systems such as belt, chain and roller conveyors.

It goes without saying that this type of equipment has to work safely. In order to do that, it needs to be installed and set up properly. It must also be made of the right material and soundly constructed. Because we have all the necessary knowledge, machines and people in-house, we can provide the best options for internal transportation. Looking for a reliable and robust solution for moving materials at your premises? Then please do not hesitate to contact us.

Do you need to transport heavy goods at your premises? Call us to find out how we can help.

Mechanical engineering

At Kepser, we know all about machines – how to put them together and how to produce them – because we’ve been doing exactly that for the last few decades. Mechanical engineering is in our blood: we started off making machines for use in mushroom cultivation back in the 1980s and our knowledge has expanded significantly since then. Today, we primarily specialise in producing machine components but if you have a particular idea or requirement for the construction of an entire machine, we would be happy to discuss it with you.

We are always extremely committed and know all the ins and outs when it comes to materials, constructions and processes, including whether something is actually feasible. Our aim is always to build a machine that will add something to the quality of the finished product. Our engineering department can turn your concept into a solution that really works. When building a new machine, it is communication between all the parties involved in the process that is the key to success. We always work with regular partners – they are easy to talk to which enables us to deliver on our promises. We are always ready to discuss our mechanical engineering solutions.

We build machines. Call to find out whether we can produce one that will be of use to you.